Author: Dr James Edmondson, VP Research at IDTechEx

Fire safety continues to be a key topic for electric vehicles (EVs) as the market continues to grow. However, EV batteries come in a range of chemistries and design, and their safety and failure modes can differ meaning that the materials employed to aid in their safety also need to meet different requirements. IDTechEx’s report, “Fire Protection Materials for EV Batteries 2025-2035: Markets, Trends, and Forecasts”, is predicting a 15% CAGR for those materials, but each battery will have its own requirements, leading to a range of material opportunities.

The types of batteries being used?

The current EV market can be largely segmented into lower energy density and cost lithium iron phosphate (LFP) and higher energy density and cost nickel manganese cobalt (NMC) chemistries. This refers to the cathode and whilst there are many subsets of these, and new variants emerging, the following discussion will largely rely on this distinction. There are also future solid-state batteries where the liquid electrolyte is removed in favor of a solid one, increasing energy density further and potentially leading to improved safety, although solid state encompasses a great range of chemistries and each one does need its own evaluation.

How likely are they to enter thermal runaway?

There are several causes of thermal runaway, including overcharging, overheating, internal short circuits, and mechanical damage. A manufacturing defect in any type of cell could cause an internal short circuit, that may lead to thermal runaway.

However, certain chemistries are better than others when it comes to thermal stability. LFP is more thermally stable than NMC, meaning it is less likely to overheat. The same is true of solid-state batteries, where the removal of a liquid electrolyte improves thermal stability.

Which batteries burn the hottest?

How hot a battery will burn may impact the choice of protection materials used. Studies suggest this is tied to the energy density of the cell. Higher nickel (and hence higher energy density) cells will exhibit higher temperatures during thermal runaway, for example, NMC 811 cells could be around 800-900°C, whereas LFP cells tend to be below 600°C.

Future solid-state cells may be less likely to enter thermal runaway, but early studies have shown that in an internal short circuit scenario, the higher energy density of solid-state batteries can see temperatures even higher than NMC, exceeding 1500°C, but this will depend on the specific type of battery and it is still early days for testing and development of solid-state batteries.

What about the gases generated?

In addition to the high temperatures reached, batteries will vent gases when in thermal runaway. Many of these gases are quite problematic from a flammability or toxicity standpoint. Similar to the maximum temperature reached, the volume of gas is tied to energy density, with high nickel NMC releasing more gas than an LFP cell. However, the composition of the gases can vary. For example, hydrogen has been shown to be a much greater proportion of the vented gas from LFP, whereas carbon dioxide and carbon monoxide are a greater proportion of NMC’s vented gases.

Summary and outlook

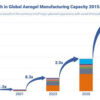

Whilst the occurrence of fires in EVs is very rare, it still poses a risk for the edge cases. There are several types of batteries and chemistries in use today and there will be new ones in the future. It would be unwise to assume that any battery is 100% safe. Therefore protection measures for these rare cases are vitally important. There are many materials for use outside the battery cells that can aid in preventing or delaying thermal runaway propagation. Materials already in use include ceramic blankets, mica, aerogels, encapsulating foams, intumescent polymers, and many more. Each battery designer will have to consider the risk profile and design of its battery system.

IDTechEx’s report on “Fire Protection Materials for EV Batteries 2025-2035: Markets, Trends, and Forecasts” is predicting a 15% CAGR for those materials. With the variety of battery designs and chemistry choices, there is a large opportunity for several types of fire protection material in this rapidly growing market.

For more information on this report, including downloadable sample pages, please visit www.IDTechEx.com/FPM.

For the full portfolio of Thermal Management research available from IDTechEx please visit www.IDTechEx.com/Research/Thermal.